Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: DJT04H

Brand: Weili

Applicable Industry: Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Turkey, Germany, Viet Nam, Chile, Canada, Italy, France, Pakistan, Saudi Arabia, Peru, Brazil, Morocco, South Korea, Colombia, South Africa

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Turkey, Germany, Viet Nam, Chile, Italy, France, Peru, Brazil, Saudi Arabia, Pakistan, India, Russia, South Africa, Colombia

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

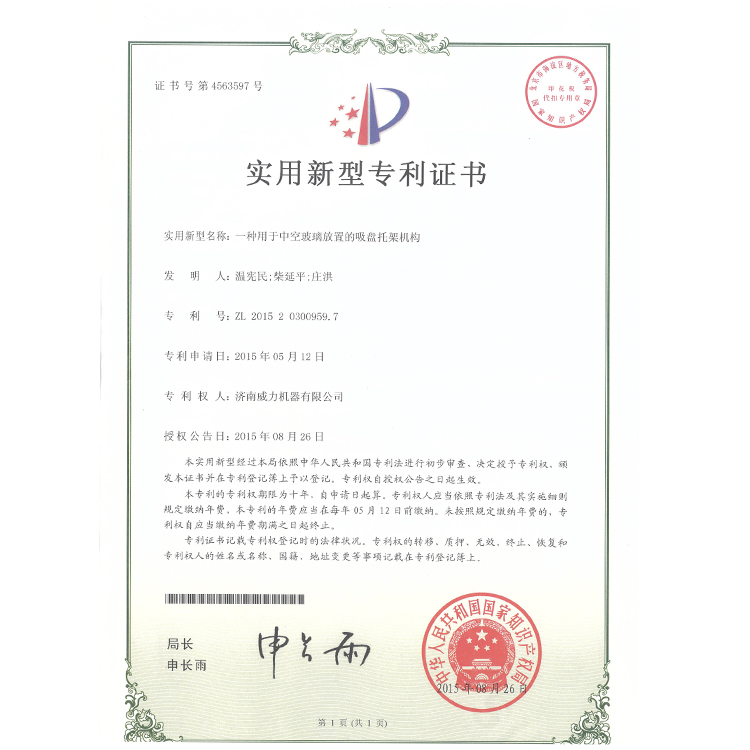

Certification: Ce, Pda

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-18mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc

Type: Insulating Glass Production Line

Structure: Vertical

Control System: Plc

Condition: New

PLC Brand: Omron From Japan

Packaging: Film and pallet

Productivity: 500 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 40 sets per month

Certificate: CE/ISO/UL/UR

HS Code: 84649019

Port: Qingdao Sea Port

Payment Type: L/C,D/P,Paypal,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA

Brief introduction:

Auto Butyl Extruder Machine can not only seal rectangle spacer bar,but round shape. Automatic Butyl Extruder Machine is a very important process in Insulating Glass Processing. Auto hot melt Extruder machine with 4 variable frequency adjustable processing speed, maximum speed: 28m/min, max glass size:2000x3000mm

Feature:

1. Insulating Glass Processing Butyl Extruder is used for the first sealing of insulating glass, butyl sealant coating.

2. Coating for straight line and arc shapes of aluminium spacer.

3. The temperature of the sealant is automatic controlled by PLC.

4. The coating effect is uniform,the efficiency is high.

5. The distance between the two sealant mouth can be adjusted, no need to release the pressure and fasten the screw,easy and convenient.

Option:

1) Working height adjustment system (Negotiate in advance of the altitude parameter, the highest altitude from the transport belt is 15mm,and the adjustment range is 3-15mm of the nozzle movement from the basic position to the highest position, including two mode: the one is 3-8mm;the other mode is 8-15mm,the default mode setting before shipping is 8-15mm mode).

2) Curve spacer added, for arc

Technical Data:

Power

AC380V, 50Hz, circa 3.5KW

Air pressure

0.6MPa

Processing spacer width

6~24mm

Efficient Butyl Volume

2 block (14L)

Main components of Hot Melt Buty Extruder

| NO. | Name | Brand |

| 1 | PLC | SCHNEIDER |

| 2 | 10.0 inch touch screen | SCHNEIDER |

| 3 | Photoelectric switch | AUTONICS |

| 4 | Limit switch | AUTONICS |

| 5 | Transducer | SCHNEIDER |

| 6 | Low voltage electric components | SCHNEIDER |

| 7 | Solenoid valve | AIRTAC |

| 8 | Cylinder | AIRTAC |

| 9 | Liner guide rail | PMI |

| 1 | Bearing of cleaning section | SKF |

| 11 | Servo motor | SIMENS / SCHNEIDER |

| 12 | Transmission motor | DPG |

Other Items of our machine

1 Automatic Butyl Extruder Machine

2 Hot Melt Glue Sealing Machine

3 Automatic Desiccant Fillng Machine

4 Manual Desiccant Filling Machine

5 Automatic Spacer Bar Bending Machine

Product Categories : Hot Melt Butyl Extruder Machine > Semi-auto Butyl Extruder Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.