Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LQ2500

Brand: Weili

Applicable Industry: Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Turkey, Germany, Viet Nam, Chile

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Turkey, Germany, Viet Nam, Chile

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-18mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2019

Core Component Warranty Period: 1 Year

Core Components: Plc

Type: Insulating Glass Production Line

Certification: PDA

Structure: Vertical

Control System: PLC

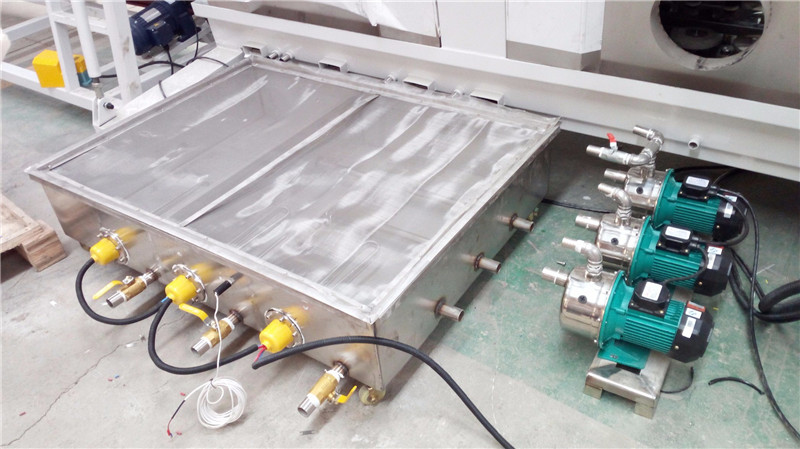

Glass Washing Machine Type: Ultrasonic Glass Washing Machine

Condition: New

Packaging: Film and pallet

Productivity: 500 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 40 sets per month

Certificate: CE/ISO/UL/UR

HS Code: 84649019

Port: Qingdao Sea Port

Payment Type: L/C,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA

Vertical Glass Washing Machine

Float Glass Washing machine used to wash float glass and Low-E glass.Our machine adopt 6 pieces brushes which controlled by cylinder.Brush and air knife can be adjusted according to 3-19mm glass.

Besides,we adopt high pressure blower which can supply more air to dry glass.Our Float Glass Washing Machine with 2000*2500,2500*3000mm,2500*3500mm,3300*6000mm model.And also can customized according to customer demands.

Features:

This machine is specially for insulating glass washing and drying. It has three sections and it is with high productin.

1. The whole process is transducer controlled, manual and automatic running model is selectable.

2. Imported Sweden SKF oil-free water proof bearings prevents the contamination to the water

3.Electric components in cabinet adopts foreign brand, like Schneider from France.

4.The cleaning section and the water tank are all made of stainless steel and corrosion-resistant materials. The transmission roller is made of acid & alkali proof rubber and it can automatically adjust the distance between the two rollers according to the thickness of the glass.

5.6 pieces brushes work together with the high-pressure water sprayers and a pair of sponge roller, guaranteeing the cleaning quality. The door is made of tempered glass and the washing conditions can be seen through the door. The water sprayers are easy to disassembly and clean. The hair of brushes is for common glass, andφ0.12mm.

6 On the back, the water tank is equipped with water heating device and Water filtering system, guarantee the temperature and cleanness.

4 7 18.5KW low voice and high pressure blower with heating device can produce circulating hot air which make drying effect reach best condition..

TTechnical parameter:

| Power supply: | 380V 50Hz |

| Air consumption: | 200L/min |

| Power: | 18kW |

| Max. process glass height | 2500*3500mm |

| Min. process dimension: | 300×450mm |

| Thickness of glass sheet: | 3~15mm |

| Max. process speed: | 45m/min |

Packing & Delivery:

1.Machine packing with plywood pallet or according to customers` requirements

2.In plywood pallet and plastic film

3.In container

After sales service

1 Online support,for example email and open camea to solve problems

2 Field installation, commissioning and training

3 Field maintenance and repair service

4 Video technical support

we help customer install machine in filed

Other items of our machine

1 Horizontal Glass Washing Machine

2 CNC Vertical Glass Drilling and Milling Machine

3 Insulating Glass Production Line

4 Insulating Glass Sealing Robot

5 Glass Washing Machine

Product Categories : Glass Washing Machine > Vertical Glass Washing Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.