Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LBW2000PD

Brand: WGM

Applicable Industry: Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Turkey, Viet Nam, Chile

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Turkey, Germany, Viet Nam, South Korea, Chile

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ul

Warranty Period: 1 Year

Core Selling Point: Famous Brand Plc

Glass Thickness: 3-18mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Plc

Type: Insulating Glass Production Line

Certification: UL

Structure: Vertical

Control System: PLC

Condition: New

Servo Motor: SCHNEIDER

Solenoid Valve: AIRTAC

Optoelectronic Switch: Autonics

Brush: Soft Brush For Low-e Glass

Packaging: plywood pallet ,plastic film, wooden package for exporting

Productivity: 650-700units/8hours

Transportation: Ocean,Land,Air

Place of Origin: SHANDONG, CHINA

Supply Ability: 220sets/year

Certificate: ISO-9001/CE/SGS/UL/CSA

HS Code: 84649019

Port: QINGDAO PORT

Payment Type: L/C,T/T,D/P,Paypal,Western Union

Incoterm: FOB,CFR,CIF,EXW

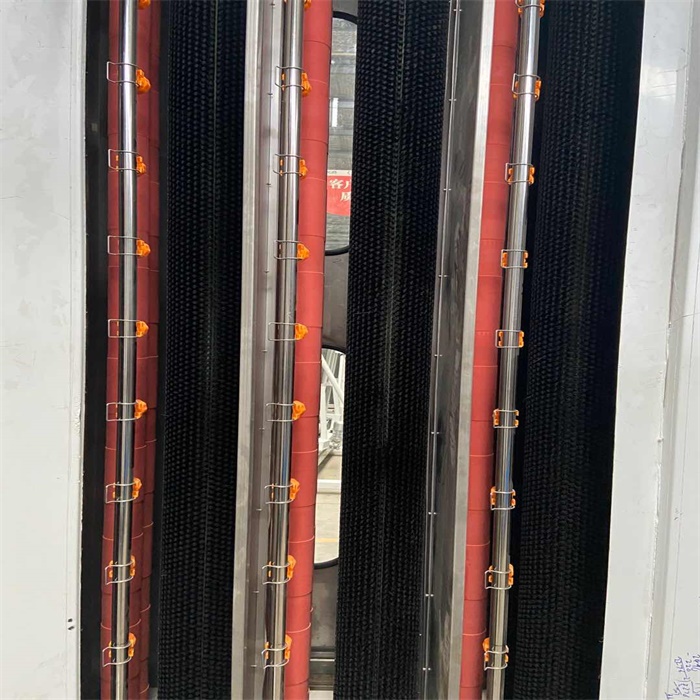

LBW2000PD Insulating Glass Processing Machinery

LBW2000PD Insulating Glass Processing Machinery adopts PLC control the working condition, this Vertical Insulating Glass Processing Linecan do outside assembly and inside flat press both ; Outside Assembly can improve the working speed, and Inside flat press part is optional for stepped glazing better; totally the line can do double glazing, triple glazing ,stepped glazing ,and also can do overlong glazing; it is multi-functional line

Specification of Main sections

washing and drying section

1. Washing section and water system adopt complete stainless steel or rot proof materials.

2. It has 3 pairs of glass washing soft brushes for coated glass and LOW-E glass.

3. Drying section adopts rubber roller to scrape of the water,and use the hot wind to dry the glass.

4. The transmit system of washing machine adopts unlimited speed adjustment to realize high efficiency of application.

Aluminum spacer put section:

this section we have side and bottom positioning to put aluminum spacer bar with high precision

Outside assembly section:

Sensor install before the press to measure glass height so that press will fill gas according to glass size ,then save more gas

3 Press secton

1. SIEMENS servo motor drive screw rolls and control press section open and close

2. Press can open 450MM for maintenance

Technical parameter

|

Technical Parameter | LBW2000PD -07 Vertical multifuctional Insulating Glass Production Line |

| Min glass size | 300*300mm |

| Max glass size | 2000*2500

|

| Washing glass thickness | 3-12mm |

| Washing glass speed | 2-12m/min

|

| Power supply | 380V/50HZ 38KW |

| Insulating max glass thickness | 50 mm

|

| Transmission glass speed | 45 m/min

|

| Air pressure | 1Mpa |

other items of our company:

1 Insulating Glass Sealing Robot

3 Aluminum Spacer Bar Bending Machine

4 Hot Melt Butyl Extruder Machine

5 CNC Vertical Glass Drilling and Milling Machine

Product Categories : Insulating Glass Production Line > Inside And Outside Assembly Flat Press Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.