Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Applicable Industry: Building Material Shops, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Algeria, Turkey, Russia

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Bangladesh, India, Turkey, South Africa

Old And New: New

Certification: Ce

Warranty Period: 1 Year

Glass Thickness: Other

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Key Words: Insulating glass machine

Washing Glass Thickness: 3-20mm

Insulating Glass Thickness: 0-80mm

Washing Speed: 0-10m/M

Transfer Speed: 0-45M/M

Production Time: 15 days

Transportation: Ocean,Land,Air,Express

Port: Qingdao Port

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: CFR,FOB,CIF,EXW,FAS,FCA,CPT,CIP,DEQ

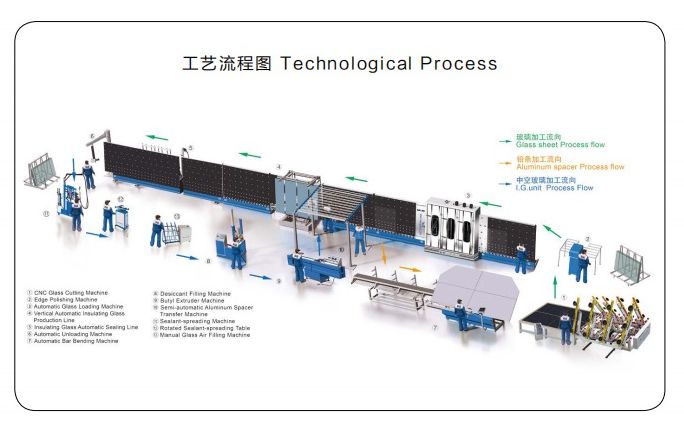

LBW2000PBVertical Automatic Insulating Glass Outside Assembly Flat Press Production Line is a high-efficiency insulating glass processing equipment. This line can not only produce ordinary insulating glass but also for low-e insulating glass. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance.It has seven parts:

1 input conveyor

2 washing section

3 inspecting sectuion

4 spacer sttaching sevtion

5 assembly conveyor

6 press machine

7 output conveyo

Main Features

(1) Adopts the PLC to control the working condition,touch screen and man-machine interface.

(2)Low-e glass automatic diagnosis system

(3) Cleans coating glass and low-e glass

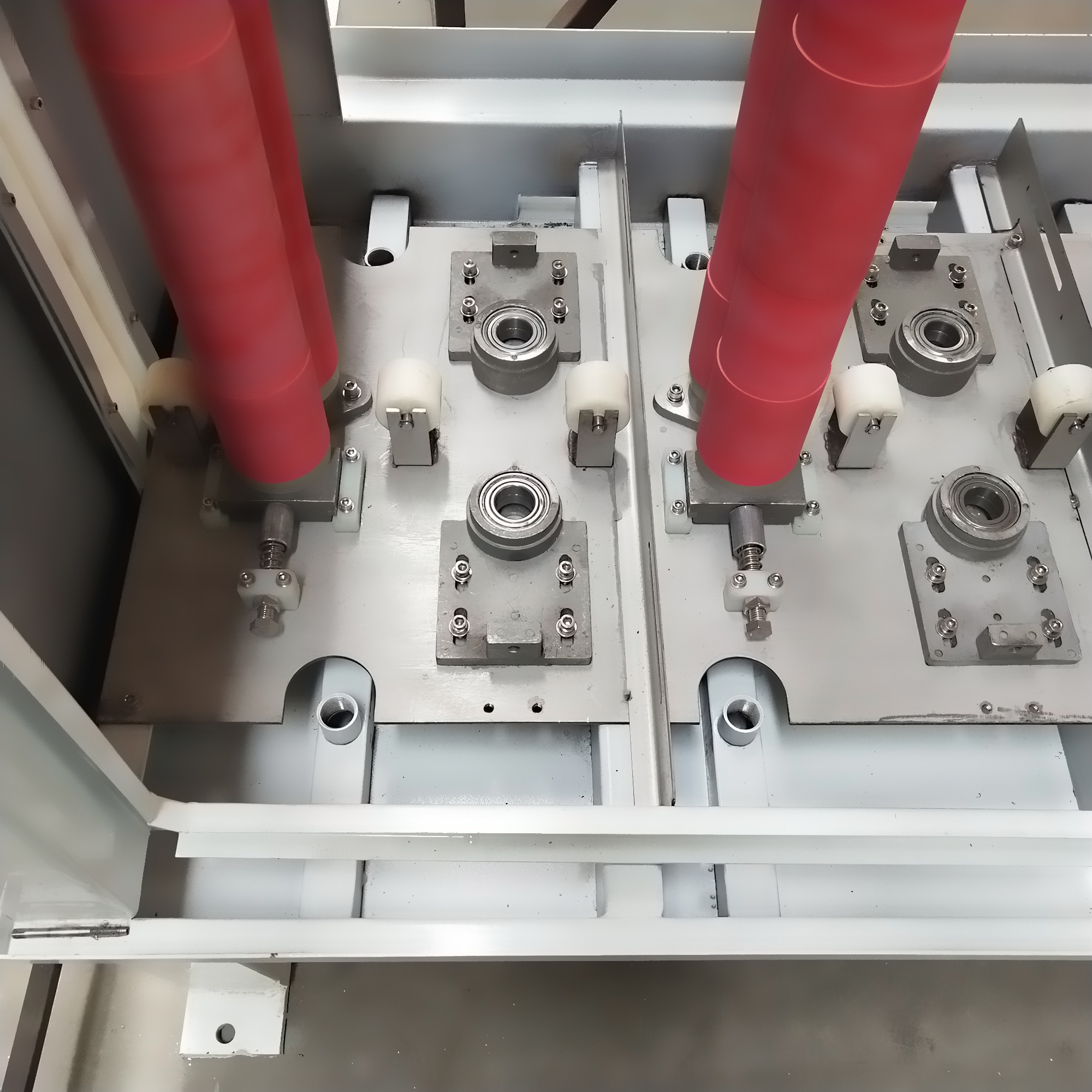

(4)Adopts no oil water-proof bearing in the washing section

(5) Conserves energy interrupted type automatic operation system

(6)Produce double glazing and triple glazing

(7)Hydrulic pressure provides power for plate press section,able to open the 450mm for maintenance.

Main Spare Part:

| NO. | Name | Brand | Brand Place |

| 1 | PLC | SCHNEIDER | FRANCE |

| 2 | 10.0 inch touch screen | SCHNEIDER | FRANCE |

| 3 | Photoelectric switch | AUTONICS | KOREA |

| 4 | Limit switch | AUTONICS | KOREA |

| 5 | Transducer | SCHNEIDER | CHINA, FRANCE |

| 6 | Low voltage electric components | SCHNEIDER | FRANCE |

| 7 | Solenoid valve | AIRTAC | CHINA, TAIWAN |

| 8 | Cylinder | AIRTAC | CHINA, TAIWAN |

| 9 | Liner guide rail | PMI | CHIAN, TAIWAN |

| 1 | Bearing of cleaning section | SKF | SWEDEN |

| 11 | Servo motor | SIMENS / SCHNEIDER | GERMANY |

| 12 | Transmission motor | DPG | CHINA |

Soft brush

It adopts custom-made and imported nylon, front is three pairs of soft brushes(Φ0.10mm), back is three pairs of hard brushes(φ0.15mm),it last the brushes life.

Successful Project

Product Categories : Insulating Glass Production Line > Inside Assembly Flat Press Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.