Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LBW2000PC

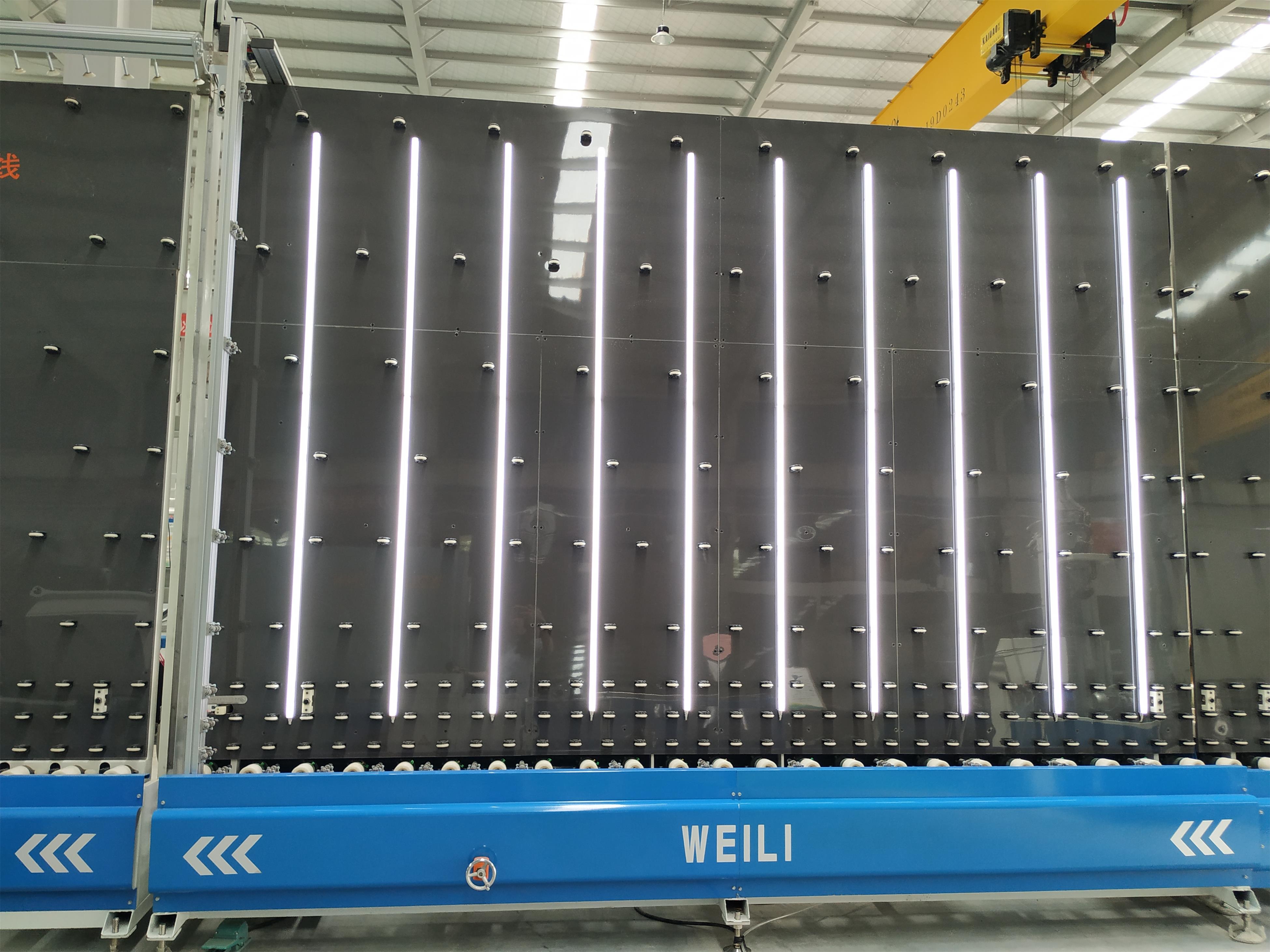

Brand: WGM & WEILI

Type: Insulating Glass Production Line

Certification: UL

Structure: Vertical

Control System: PLC

Condition: New

Flow Volume: 0.8m3/min

Compressed Air: 800L/min

Min.glass Size: 300x400mm

Air Pressure: 1Mpa

Max.glass Size: 2000x2500mm

Packaging: plywood pallet and plastic film

Productivity: 650-700units / 8hours

Transportation: Ocean,Land

Place of Origin: Shandong, China

Supply Ability: 100 sets/year

Certificate: ISO-9001/CE/SGS/UL/CSA

HS Code: 84649019

Port: Qingdao Port

Payment Type: T/T,D/P

Incoterm: FOB,CFR,CIF,EXW

Automatic Insulating Glass Processing Machine for LOWE Glass adopts PLC control system, touch screen operation. The cleaning section adopts soft brush, which can clean LOW-E and coated glass. Insulating Glass Processing Machine for LOW-E process stepped insulating glass and triple insulating glass are available. Frequency speed control for glass transmission. The output is 500~700 pcs IG units per 8 hours (Double glazing IGU, size 1M). Double Glazing Glass Processing Machine flat press gas filling section uses a servo motor to drive the synchronous belt, which has the functions of tablet pressing and inflation. IDouble Glaizng Insulating Glass Production LineIt adopts advanced assembly technique and solves the problems of uneven press and misplacement of the glass.

Technical parameter

| Power Supply | 380V/50HZ 37.5Kw |

| Dimension(LxWxH) | 21300x2600x3050mm |

| Production quantity | 700-800IG units/8hs |

| Max Glass Size | 2000x2500mm |

| Min Glass Size | 350x400mm |

| Washing Glass Thickness | 3-15mm |

| Washing Glass Speed | 0-10m/min |

| Insulating Glass Thickness | ≤48mm |

| Transmission Glass Speed | 0-45m/min |

| Compressed Air: | 800L/min |

| Air Pressure: | 0.7Mpa |

| Environment Temperaturer | 7~50℃ |

| Brush | 6 pieces, include 3 LOW-E brushes |

More details:

Washing and Drying sector(★Using 304 stainless steel, the pre washing section is optional★)

Outside assembly section(★ Working more efficiency★)

Gas Filling Inside Press section(★ Argon gas concentrate is alway higher than 85%, can meet CE demands ★)

After-sales service:

* Provide factory layout according to your factory size in advance

* Provide English Version of Installation/Operation/Service/Maintenance Manual.

* Engineers available to service machinery overseas.

* Online support

* Video technical support

* Field maintenance and repair service

* Field installation commissioning and training

Company information:

Our Company establishde in 2001 and with 19 years history which specialize in insulating glass machine.

Machine exported to more than 60 countries,such as America,Canada,Russia,Turkey,Australia,Vietnam,India and so on.

Product Categories : Insulating Glass Production Line > Automatic Insulating Glass Gas Filling Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.