Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LBW2000PC

Brand: WGM

Applicable Industry: Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Mexico, Romania, Canada, Russia, Bangladesh

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Mexico, Russia, Kyrgyzstan, Ukraine, Turkey, Spain, Nigeria

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce, Ul

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-18mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Other

Core Component Warranty Period: 1 Year

Core Components: Plc

Type: Insulating Glass Production Line

Structure: Vertical

Control System: Plc(Schneider)

Condition: New

Min Glass Size: 300x400mm

Insulating Glass Thickness: 0-48mm

Application: Making Insulating Glass

Max Glass Size: 2500x3500mm

Colour: Blue And Black (Customerized)

Packaging: plywood pallet and plastic film

Productivity: 600-650units/8hours

Transportation: Ocean,Air

Place of Origin: SHANDONG, CHINA

Supply Ability: 200sets/year

Certificate: ISO/CE/SGS/UL/CSA

HS Code: 84649019

Port: QINGDAO PORT

Payment Type: L/C,T/T,D/P

Incoterm: FOB

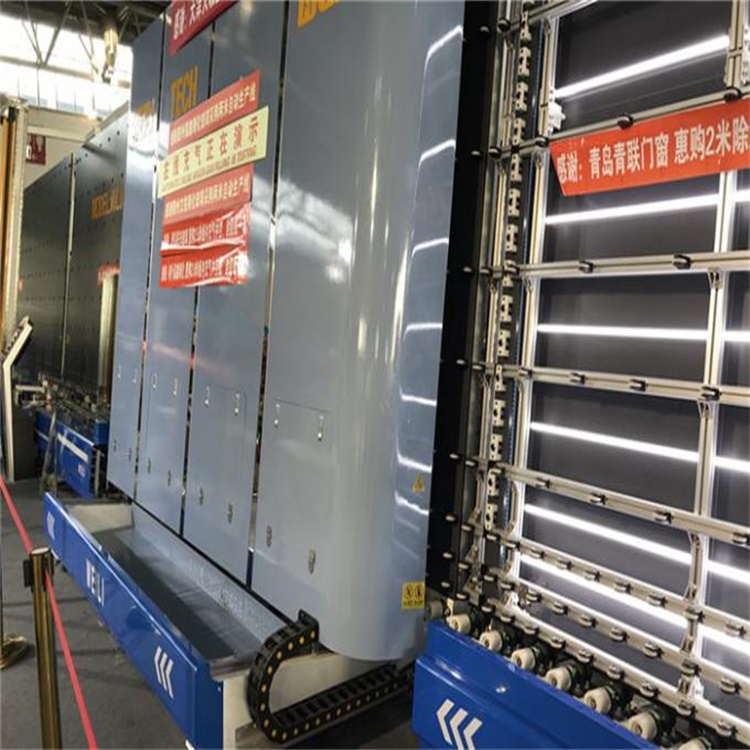

LBW2000PC CNC automatic Insulating glass processing machines for sales/glass processing machine

WGM-LBW2000PC MODEL Inside Assembly Flat Press Production Line contains seven or six sections: glass input section, vertical glass washing and drying section, storage section, aluminum spacer bar and light glass section, outside assembly section(option); Inside Assembly Flat Press Production Line with argon gas filling; glass output section; it can fill argon gas more than 90%; meanwhile can save argon gas more than 95% to reduce the waste of argon gas; It is mainly used in processing insulating glass, especiaily for window, door, curtain wall and so on; This Inside Assembly Flat Press Production Line has CE certification and ISO-9001 both, so it has good sales in domestic and foreign market;

Feature:

1.Achieve the functions of outside and inside assembly, automatically fill argon gas.

2.Adopts the Schneider PLC to control the working condition and touch screen.

3.Automatic detect coated surface of coating glass and Low- E glass.

4.Air knife can automatic adjust according to glass thickness.

5.Brushes’ rotate speed variable frequency drive.

6.Aluminum spacer and glass automatic positioning system.

7.Automatic detect the length and height of glass, automatic adjust the best gas filling time.

8.Automatic gas filling press machine adopt 4 servo motors, which has assembling, pressing and automatic argon gas filling

function.Ensure the insulating glass argon gas concentrate ≥90%.

9.It has remote monitor and program upgrade functions.

Main Electrical Components:

| No. |

Name

| Brand | Brand Place |

| 1 |

PLC | Schneider | France |

| 2 |

10.0inch Touch Screen(10.0) | Schneider | France |

| 3 |

Photoelectric Switch | Autonics | S.korea |

| 4 |

Limit Switch | Autonics | S.korea |

| 5 |

Transducer | Schneider | France |

| 6 |

Low-voltage electric components | Schneider | France |

| 7 |

Straight Guide Rail | HIWIN | China |

| 8 |

Driving Wheel | Polyurethane | China |

| 9 | Soft Brushes | φ180mm High Temperature Nylon Can wash low-e glass | China |

| 10 |

Cleaning Section | 304 Stainless steel | China |

| 11 |

Bearing of Cleaning Section

| SKF(oil-free lubrication waterproof) | SWEDEN |

| 12 |

Transmission Motor | Chengbang | CHINA Taiwan |

| 13 |

Hydraulic Parts | HUADE | China |

| 14 |

Pneumatic components, like solenoid valve, air cylinder | SMC | Japan |

| 15 |

Servo motor | SIMENS | GERMANY |

| 16 |

Driver | SIMENS | GERMANY |

| 17 |

LOWE SENSOR | KEYENCE | JAPAN |

Technical Parameter:

|

Power Supply | 380V/50HZ 37.5Kw |

|

Dimension(LxWxH) | 21600*2800*3450mm |

|

Production quantity | 600-650IG units/8hs |

|

Gas filling percent | ≥90% |

|

Max Glass Size | 2500x3500mm |

|

Min Glass Size | 300x450mm |

|

Washing Glass Thickness | 3-15mm |

|

Washing Glass Speed | 0-10m/min |

|

Insulating Glass Thickness | ≤48mm |

|

Transmission Glass Speed | 45m/min |

|

Compressed Air | 0.8m³/min |

|

Gas filling time | 3~5S |

|

Air Pressure: | 0.7Mpa |

|

Environment temperature | 7-50℃ |

Service:

| Pre- sale service | After - sale service |

| * Inquiry and consulting support.

* Professional customize

* Visiting our factory.

* Provide factory layout according to your factory size in advance | * Provide English Version of Installation/Operation/Service/Maintenance Manual.

* Online support

* Engineers available to service machinery overseas.

* Video technical support

* Field installation commissioning and training

* Field maintenance and repair service |

The washing and dry section

►Use 304 stainless steel. can wash 3-19mm thickness glass.

►The brush of the washing part is soft brush which can wash LOW-E glass.

►There is 6 motors and six brushes on this part, high efficiency.

►The bearing on this part is SKF bearing with stainless steel material.

It is water-proof bearing which can prolong the life of the machine.

►The distance between the red drag roller and air knife can adjusted automatically according to the glass thickness.

Other related items of our company:

1. Insulating Glass Production Line

2. Low-E Coating Remover Machine

3. LOW-E Coating Remover Machine

4. Aluminum Spacer Bar Bending Machine

5. Glass Washing Machine

Flat press Section

♦Linear guides, ball screw, synchronous belt and servo motor to drive

which make the press stable and precise.

♦Online automatic argon gas filling function .Argon gas is≥90%(1mx1m)

♦It can open 450mm for maintenance

Our office & factory:

Package:

1.Machine packing with plywood pallet or according to customers` requirements

2.In plywood pallet and plastic film

3.In container

The normal package is plywood pallet and plastic film or pack it according to customers special requests.

Product Categories : Insulating Glass Production Line > Automatic Insulating Glass Gas Filling Production Line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.