Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Wl2000

Brand: Weili

Applicable Industry: Construction Works, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, Uae, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Egypt, Canada, Turkey, United Kingdom, United States, Italy, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Kenya, Argentina, South Korea, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Kyrgyzstan, Nigeria, Uzbekistan, Australia, Morocco

Old And New: New

Machine Type: Insulating Glass Production Line

Place Of Origin: China

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Glass Thickness: 3-19mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Core Components: Plc

Type: Insulating Glass Production Line

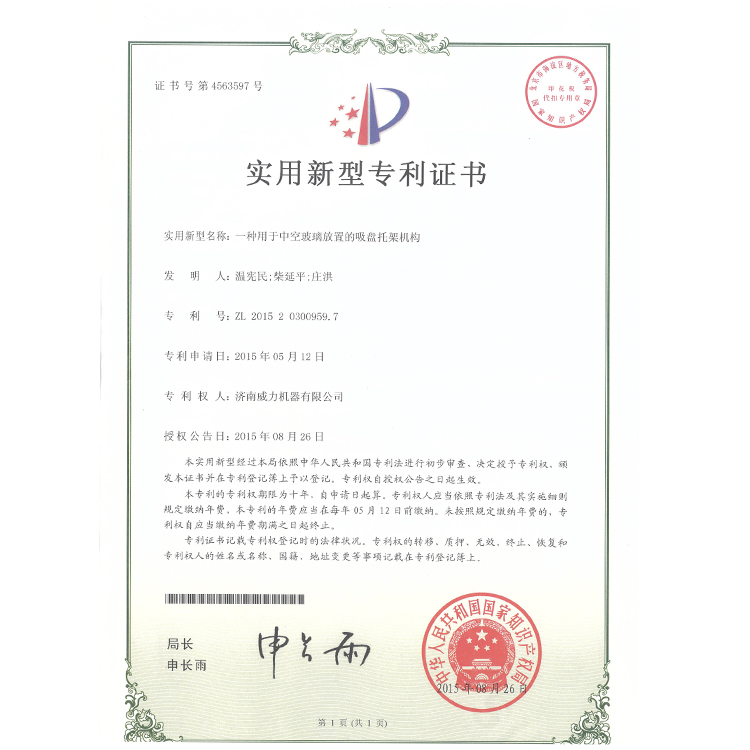

Certification: PDA

Structure: Vertical

Control System: PLC

Glass Washing Machine Type: Ultrasonic Glass Washing Machine

Condition: New

Packaging: Film and pallet

Productivity: 500 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 40 sets per month

Certificate: CE/ISO/UL/UR

HS Code: 84649019

Port: Qingdao Sea Port

Payment Type: L/C,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA

This Rubber Sealant Hot Melt Butyl Machine is used for butyl sealant coatingon both sides of aluminum spacer frame and temperature is automatically controlled with high stability,It is one step of insulating glass machine to product the insulating glass.

1. insulating glass machine height adjustment is available according to the frame size.

2. The nozzle width shall be controlled by pneumatic and hydraulic parallel method.

3. Conveyor speed can be adjusted with 5 conveyor speed.

4. Possible to control the length of butyl application and monitoring current production quantity on the touch screen.

5. insulating glass machine can seal the circle aluminum(as pictures following)

6. insulating glass machine adopt Germany pneumatic pump,brand Maximator.

Technique parameter:

| Machine size | 3000mm(L)x600mm(W)x950mm(H) |

| Spacer width | 6mm-25mm |

| Minimal size | 250mmx250mm |

| Maximal size | 2500mmx2500mm |

| Speed | 0-25m/min |

| Butyl volume | 14L |

| Power supply | AC380V 3ph 50HZ |

| Total power | 3.75kw |

Main components

| NO. | Name | Brand |

| 1 | PLC | SCHNEIDER |

| 2 | 10.0 inch touch screen | SCHNEIDER |

| 3 | Photoelectric switch | AUTONICS |

| 4 | Limit switch | AUTONICS |

| 5 | Transducer | SCHNEIDER |

| 6 | Low voltage electric components | SCHNEIDER |

| 7 | Solenoid valve | AIRTAC |

| 8 | Cylinder | AIRTAC |

| 9 | Liner guide rail | PMI |

| 1 | Bearing of cleaning section | SKF |

| 11 | Servo motor | SIMENS / SCHNEIDER |

| 12 | Transmission motor | DPG |

WEILI Glass Machine welcome you to visit us!

Other related items of our company:

1. Insulating Glass Production Line

2. Low-E Coating Remover Machine

3. Automatic Insulating Glass Unloading Machine

4. Aluminum Spacer Bar Bending Machine

5. Glass Washing Machine

Product Categories : Hot Melt Butyl Extruder Machine > Automatic Butyl Extruder Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.