Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: LWJ01

Brand: WGM

Type: Insulating Glass Production Line

Certification: PDA

Structure: Vertical

Control System: PLC

Glass Washing Machine Type: Ultrasonic Glass Washing Machine

Glass Edging Machine Type: Glass Double Edging Machine

Grinding Head Number: 6

Condition: New

Power: 1KW

Machine Name: Insulating Glass Aluminum Spacer Bending Machine

MACHINE FUNCTION: Insulating Glass Aluminum Spacer Bending Machine

Max Frame Size: 2500*3000mm

Min Frame Size: 250*380mm

Size Tolerances: 250*380mm

Angle Tolerances: <1mm

Dimension(L.W.H): 4000*1300*1700mm

Color: Made It By Customize

Period: 1 Year

Packaging: plastic plywooden

Productivity: 700-800 units

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200 sets per year

Certificate: CE

HS Code: 84649019

Port: QINGDAO PORT

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

Bending machine for Aluminum Profile

LWJ01 spacer bar frame bending machine can be use for aluminum frames for U-type aluminum profile doubleglazing glass. Automatic 32 Different Shapes of Spacer Bar Bending Machine with strong capacity, competitive costs, extensive application, convenient & flexible operational panel in Chinese, the spacer bending machine can significantly promote production efficiency for the weak link in fabrication of laminated glass and consequently promoted the grade of the products.Spacer Bar Bending Machine can not only bend the rectangle,it also can bend the circle,triangle about 32 shapes of aluminum spacer bar.

| Power supply | 2P 220V/50HZ |

| Total power | 2.5KW |

| Air pressure | 0.5~0.8Mpa |

| Min spacer frame size | 250*250mm |

| Max spacer frame size | 2500*3000mm |

| Spacer width range | 5.5mm~23.5mm |

| Overall dimension | 10500*2100*2200mm |

| Production tolerances | +/- 0.5mm |

Our related products:

Insulating Glass Machine

CNC Vertical Glass Drilling and Milling Machine

Vertical Auto Gas Filling Production Line

1) The whole machine is controlled by Siemens PLC. The Man-machine contact screen is Taiwan winview brand.

The whole machine features easy and quick operation.

2) It adopts the Japan FUJI servo motor system to feed and bend the aluminium bar. The efficiency and bending

precision are high.

3) It adopts Taiwan Airtac pneumatic components. The movements of the machine are precise and reliable.

4) The machine is eauipped with four storage area and can store four different size of aluminium bar.

5) When bending and cutting, the machine will automatically avoid the connection parts of the

aluminium bar and the circle arc parts. After bending, the machine will cut the bar automatically.

6) It can be operated manually so it is easy to debug and maintain the machine.

7) The machine can produce 32 different shapes of aluminium bar, including the triangular, rectangle, positive

pentagon, circle arc with a straight line.

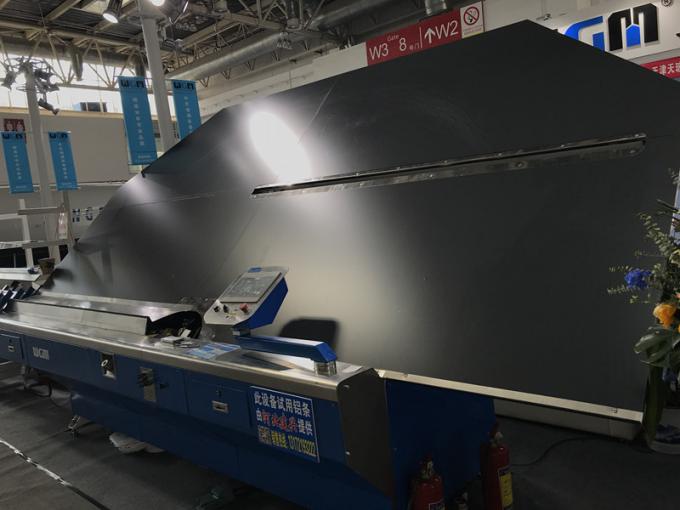

Real photos:

►can produce 32 different shapes of aluminium bar, including the triangular, rectangle, positive

pentagon, circle arc with a straight line.

►The max spacer frame size is 2500x3500mm.

►When bending and cutting, the machine will automatically avoid the connection parts of the

aluminium bar and the circle arc parts. After bending, the machine will cut the bar automatically.

►The machine is eauipped with four storage area and can store four different size of aluminium bar.

FAQ

1.Q:Are you manufacture?

Yes,we are the professional manufacture which have more than 5 workshops.

2.Q: How about the service ?

1).reply it at once if from Ali-trademanager,if by email,it reply it within 12 hour

2).deliver max. days within 15 days

3).more than 22 years experience in this kind machine field

4).fluent English ,communication barrier free

3.Q:What's the guarantee ?

1).Our guarantee for 12 months.

2).24 hour's technical support by email or calling

3).English manual and video tutorial

4).2 year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

4. Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

Product Categories : Aluminum Spacer Bar Bending Machine > Automatic Aluminum Spacer Bar Bending Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.